Introduction

Knife making is an ancient craft that continues to captivate people today. From utilitarian tools to works of art, knives are created from an array of different materials that provide unique properties and aesthetics. When making a knife, thoughtfully choosing materials based on the knife's intended purpose and personal preferences is key.

The most essential material decision is selecting the steel for the blade itself. Steels have varying characteristics that affect the blade's sharpness, edge retention, stain resistance, and ease of maintenance. Handle materials also diversify greatly, from rugged stability to intricate artistry. Additionally, factors like balance, grip, and overall feel must be weighed. The fittings and embellishments offer further customization. Mastering material selection unlocks new realms of possibility in knife making.

Steel Blade Materials

As the part responsible for cutting, the blade steel sets the foundation for knife performance. Carbon steels have moderate corrosion resistance but excel in hardness for exceptional edge retention. 1095 high carbon steel is a popular choice as it sharpens easily to a keen edge, though rust can develop if not cared for. Adding chrome and nickel creates stainless steels, which resist corrosion through increased chromium content but tend to be softer. 154CM and 440C stainless are used widely for their rust resistance and good edge qualities. Going beyond stainless steel, tool steels have heightened versatility from additional alloys like molybdenum, tungsten, or vanadium. These enhance properties like toughness, hardness, and wear resistance. D2 tool steel has proven endurance for hard-use knives while retaining decent stain resistance.

Exploring how different steels strike a balance between corrosion resistance, edge qualities, and ease of resharpening allows knife makers to select the right blend of attributes based on intended usage. A knife meant for daily carry and utility purposes would benefit more from stainless steel or tool steels optimized for ruggedness rather than carbon steels, which require vigilance against rust. Contrastly, a custom showpiece not meant for hard use could indulge fully in a carbon steel blade for peerless sharpness.

Handle Materials

The handle covers a wide range of natural and synthetic mediums, each imparting a distinct look and feel. Wood remains a popular choice, offering a traditional, organic aesthetic with grains that make every handle unique. Oily woods like rosewood provide water resistance, while stable woods like maple suit heavier-use knives. Artisans can shape and carve wood into ergonomic comfort, though stability varies across wood species.

For exceptional toughness, bone and antler handles withstand compression and wear, weathering beautifully over years of use. Their roughness aids grip while showcasing natural variation through marbling and color distinctions in the material. However, moisture can warp bone over time, which impacts its integrity. On the more modern end, fiberglass-reinforced nylon (FRN) creates lightweight and grippy handles that are able to withstand extreme temperatures, chemicals, and regular wear and tear thanks to the synthetic composition.

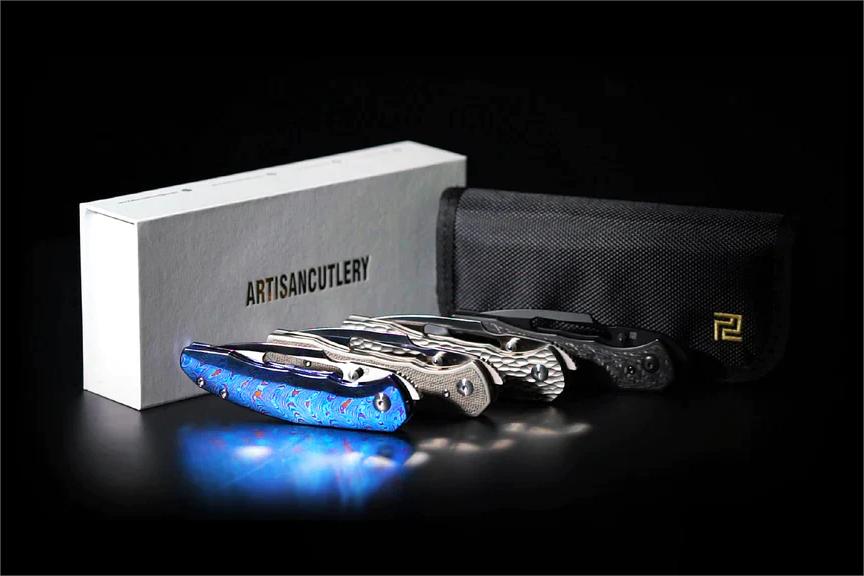

Metals like stainless steel, titanium, and aluminum fashion sleek, durable handles while allowing custom embellishments through engraving, stonewashing, or anodization. Their innate waterproofing tolerates rough handling. Titanium displays an especially impressive strength-to-weight ratio. Still, prolonged cold exposure to bare metal can chill the user's hands. Modern composites like G10 and Micarta fuse various materials like glass fiber, resins, or linen into laminates. This fortifies strength and reliability suitable for hard-use knives while permitting texturizing for an ideal grip.

Personal preferences tend to dictate handle selections based on aesthetics, ergonomics, and intended conditions of use. A knife expected to undergo heavy abuse would prioritize stronger composites like G10 over natural materials like bone, which, while eye-catching, lacks the same resilience. For hunters and survivalists who rely on their blade's performance in adverse weather, waterproofing becomes necessary as well.

Fittings

The cumulative details distinguish a serviceable knife from a spectacular knife. Fittings embellish through functional flair. For example, bolsters reinforce the knife's front and rear by the handle, curbing wear over years of use. Nickel silver bolsters complement lighter handle materials like wood without stealing the show. Meanwhile, polish rose gold bolsters lend striking embellishment.

Pins act as fasteners between the blade and handle while doubling as aesthetic accents. Brass pins make a timeless statement, though nickel silver and stainless steel pins integrate more durably into the knife. Going further, mosaic pins weave colorful composite pins together through segmentation, yielding mesmerizing visual texture. Backspacers similarly separate the handle scales while introducing luster. Here, anodized titanium and mokume gane boutique metals generate brilliance, though any material can be utilized.

End caps known as pommels balance the knives' backend visually yet also improve grip security. Wood, acrylic, and precious stone pommels prove ever elegant while integrated paracord wraps infuse functionality, allowing survivalists to unravel cordage in crisis. Engraved logo pommels elicit prestige through masterful chiselwork. Truly, pommels enhance ergonomic authority behind the knife's profile. With such an expansive selection of metals, composites, and natural materials at play, the only limit is imagination itself when outfitting knife fittings.

Choosing Materials Properly

Blending suitable materials ultimately comes down to the purpose and tastes unique to each knife maker and owner. If a utilitarian cutting tool geared for daily use is the aim, stainless steel blades join forces best with hardy handle materials like G10 that withstand abrasion while championing grip security with texturized handles. Pommels can further fine-tune ergonomics and grip support where hands make contact.

Conversely, traditional pocket knives meant for gentlemen duties like opening letters rely foremost on style. Here, exotic woods like snakewood carry intrigue and conversance, especially when paired with nickel-silver bolsters broadcasting understated unity. While perhaps not the optimal materials for dismantling backcountry shelters in heavy precipitation, such knives channel old-world charm through selective pairings.

For those seeking resilience and artfulness alike, pairings like D2 tool steel blades and figured maple wood handles adorned with mosaic pins harmonize lasting performance with an ageless beauty that only improves after years of wear. Ultimately, the knife maker must reflect on which elements hold priority - strength, grace, longevity, rustic heritage, modern minimalism - and make material selections accordingly based on personal taste and knife-destined duty.

Conclusion

From ancient times until now, the substance of knives channels both practicality and personality. The dazzling array of metals, natural materials, and composites power bladesmiths to mix and match for ideal pairings tuned precisely to purpose and preference. While intimidating initially, grasping fundamentals of key properties from edge integrity to corrosion resistance, ergonomic authority to aesthetic allure allows makers to traverse material decisions with confidence and intent. When artistry and performance strike a balance through mindful selections fitted to the knife's destiny, transcendent results are unlocked. The journey of material mastery beckons all who would answer the siren call of the bladesmithing arts.

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.